Our Courses

Lean Process And Six Sigma

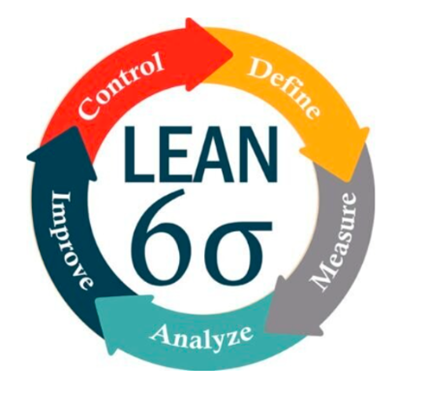

Six Sigma is a data-driven approach for eliminating defects and waste in any organization by treating the processes within the business so that they deliver their intended result.

Our Lean Process And Six Sigma workshop will provide an introduction to this way of thinking, that has changed so many corporations around the world. This workshop will give participants an overview of the Six Sigma methodology, and some of the tools required to deploy Six Sigma in their own organizations.

*This course pairs well with Business Acumen and/or Business Ethics, in developing/enhancing essential business skills

Course Objectives:

- Develop a 360 degree view of Six Sigma and how it can be implemented

- Identify the fundamentals of lean manufacturing, lean enterprise, and lean principles

- Describe the key dimensions of quality – product features and freedom from deficiencies

- Develop attributes and value according to the Kano Model

- Understand how having the right products and services promote customer satisfaction

- Understand how having the right products and services attract and retain new customers

- Describe what is required to regulate a process

- Review examples of how poor quality affects operating expenses in the areas of appraisal

- Review examples of how poor quality affects internal and external failure cost

- Review examples of how poor quality affects inspection cost

- Using basic techniques such as DMAIC and how to identify Six Sigma Projects

- Use specific criteria to evaluate a project

- Discover root causes of a problem

Course Outline:

Lean Process And Six Sigma

Module One: Understanding Lean

• About Six Sigma

• About Lean

• History behind Lean

• Toyota Production Systems

• The Toyota Precepts

Module Two: Liker’s Toyota Way

• Philosophy

• Process

• People and Partners

• Problem Solving

Module Three: The TPS House

• The Goals of TPS

• The First Pillar

• The Second Pillar

• Kaizen

• The Foundation of the House

Module Four: The Five Principles of Lean Business

• Value

• Value Stream

• Flow

• Pull

• Seek Perfection

Module Five: The First Improvement Concept (Value)

• Basic Characteristics

• Satisfiers

• Delighters

• Applying the Kano Model

Module Six: The Second Improvement Concept (Waste)

• Muda

• Mura

• Muri

• The New Wastes

Module Seven: The Third Improvement Concept (Variation)

• Common Cause

• Special Cause

• Tampering

• Structural

Module Eight: The Fourth Improvement Concept (Complexity)

• What is complexity?

• What causes complexity?

• How to Simplify

Module Nine: The Fifth Improvement Concept (Continuous improvement)

• The PDSA Cycle (Plan, Do, Study, Act)

• The DMAIC Method

Module Ten: The Improvement Toolkit

• Gemba walks

• Genchi Genbutsu

• Womack’s Principle

• Kaizen

• A Roadmap for Implementation

Module Eleven: Assignment Review / Wrap Up